FORKLIFT GUIDANCE SYSTEM

UPGRADE MANUAL VEHICLES

TO AUTOMATED SYSTEMS

Optimize forklift and tugger train operations with real-time tracking, seamless communication,

and intuitive in-vehicle interface, all fully integrated into the NAiSE Intralogistics Platform.

OUR SOLUTION

INTELLIGENT MANAGEMENT FOR HUMAN-DRIVEN VEHICLES

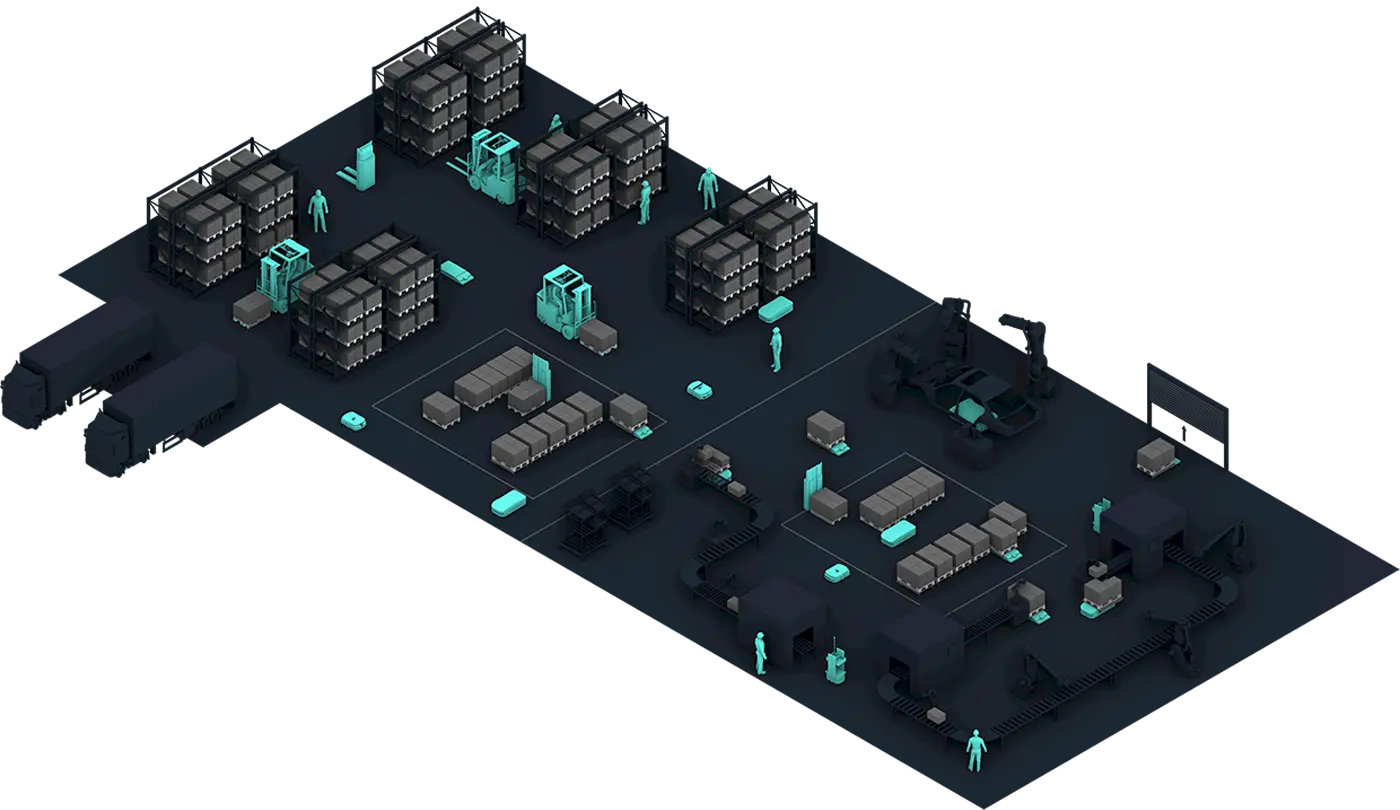

The Forklift Guidance System by NAiSE transforms traditional forklift and tugger train operations into a fully connected, intelligent ecosystem. By integrating Traffic, Order and Warehouse Management into a single module, it enables real-time coordination and seamless communication for human-driven vehicles. With advanced localization technology and a dedicated Order Execution Terminal, every vehicle becomes a visible and manageable participant within intralogistics workflows, bridging the gap between manual operations and automated systems.

TRANSPARENT.

REAL-TIME VISIBILITY OF MANUAL VEHICLES

Gain full visibility into the location, status, and tasks of all human-driven vehicles in real time, ensuring informed decision-making and eliminating operational blind spots.

FLEXIBILE.

SEAMLESS INTEGRATION WITH EXISTING OPERATIONS

SIMPLE.

INTUITIVE INTERFACE FOR OPERATORS AND MANAGERS

Simplify daily operations with intuitive interfaces and direct communication to vehicles, allowing operators and managers to execute tasks efficiently without disrupting existing processes.

DOES YOUR SYSTEM SUPPORT RTLS SOLUTIONS?

LOCALIZATION OF A HUMAN-OPERATED FLEET !

NAiSE Intralogistics Platform integrates all intralogistics participants, including forklifts and tugger trains, via our in-house UWB-based RTLS or third-party solutions. The platform is compatible with the omlox localization standard, ensuring future-proof integration.

TRAFFIC MANAGEMENT

SMART TRAFFIC ORCHESTRATION

NAiSE Traffic Manager enables efficient coordination of forklifts and tugger trains within intralogistics environments. By processing real-time localization data, the system monitors every vehicle’s position, predicts potential conflicts, and dynamically adjusts traffic flow to avoid collisions and bottlenecks. Manual vehicles become part of a centrally managed ecosystem where routes are optimized, priorities are balanced, and movements are continuously synchronized with overall intralogistics processes.

ORDER MANAGEMENT

DIGITAL TASK COORDINATION

WAREHOUSE MANAGEMENT

SMART INVENTORY FLOWS

NAiSE Warehouse Manager connects manual vehicles like forklifts and tugger trains directly to warehouse operations. Through the NAiSE platform, drivers can execute tasks related to inventory handling, including rebooking handling units, directly from the Order Execution Terminal. This integration ensures transparent material flow, reduces manual errors, and bridges the gap between transport operations and warehouse processes.

REAL-TIME LOCALIZATION

PRECISE VEHICLE TRACKING

NAiSE Forklift Guidance System uses Real-Time Localization System (RTLS) technology to integrate forklifts and tugger trains into warehouse operations. By supporting both NAiSE’s UWB-based RTLS and third-party solutions, the platform ensures flexibility for different facility setups. Real-time position data flows directly into the NAiSE system, enabling managers to optimize routes, avoid collisions, and streamline task execution across intralogistics.

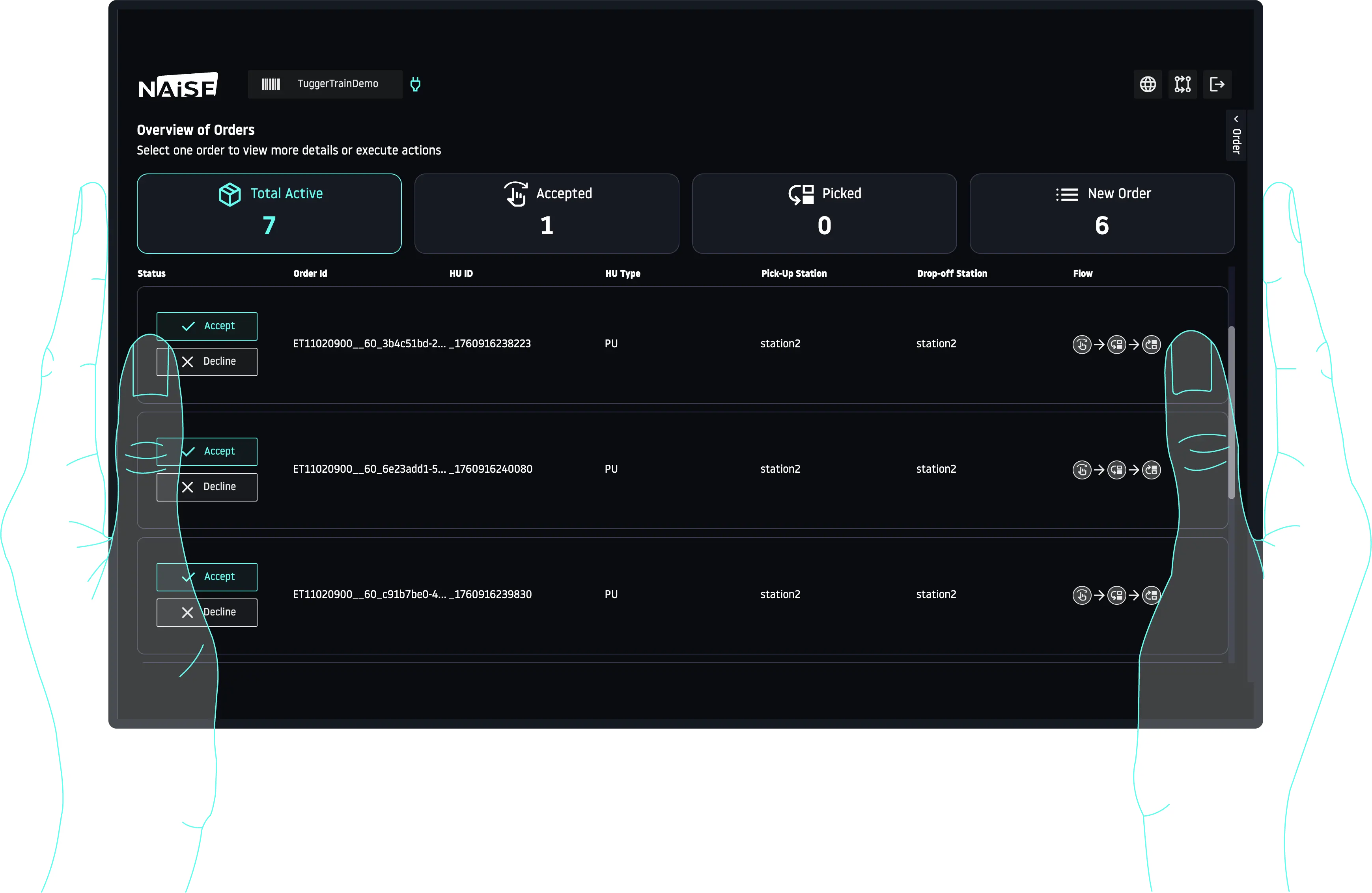

NAiSE ORDER EXECUTION TERMINAL

CENTRAL HUB FOR FORKLIFT AUTOMATION

The Order Execution Terminal is built to empower drivers, streamline workflows, and ensure every task is executed efficiently. Its intuitive interface and real-time connectivity turn manual vehicles into fully integrated, responsive participants in your intralogistics operations.

OVERVIEW OF TASKS

STAY ON TOP OF EVERY TASK

Drivers get a complete overview of all assigned tasks, including priorities and deadlines. This ensures nothing is missed and allows for better planning throughout the shift. Visibility into the workflow keeps operations organized and efficient.

TASK EXECUTION INSTRUCTIONS

EXECUTE WITH CONFIDENCE

Step-by-step guidance provides clear instructions for every task, reducing errors and boosting productivity. Drivers can focus on execution without second-guessing what to do next. Efficiency and accuracy are built into every move.

REAL-TIME COMMUNICATION OF NEW TASKS

INSTANT UPDATES, NO DELAYS

New or updated tasks are communicated in real time, allowing drivers to react immediately to changing priorities. No more waiting or miscommunication—operations stay fluid and responsive. Every change is captured instantly for complete transparency.

FEATURES

TRACK. OPTIMIZE. DELIVER.

- Reliable Positioning: UWB Anchors create a robust positioning network with accurate coverage across your facility.

- Centralized Data: UWB Gateways transmit real-time location data to the NAiSE Intralogistics Platform for fleet coordination and operational intelligence.

- Continuous Updates: UWB Tags on vehicles or equipment provide real-time tracking, even in complex environments.

- Optimized Operations: System-level integration supports swarm intelligence for multiple vehicles operating simultaneously.

- Self-Optimizing Network: Adaptive mesh networking ensures scalability and minimal manual intervention.

- Easy Installation: Quick setup reduces operational disruption and downtime.

INTELLIGENT

FLEET MANAGEMENT

OPTIMIZED

MATERIAL FLOW

SEAMLESS COORDINATION

COMPONENTS

HIGH-PRECISION REAL-TIME TRACKING

NAiSE UWB ANCHORS

ANCHORS AS POSITIONING BACKBONE:

- Designed for ceiling or wall installation.

- Ensure reliable and accurate communication across the facility.

- Keep away from metallic obstacles and orient correctly to maximize coverage.

NAiSE UWB GATEWAYS

GATEWAYS ACT AS DATA AGGREGATORS:

- Collect signals from anchors and tags.

- Transmit location data to the NAiSE Intralogistics Platform.

- Provide a centralized source for fleet coordination and operational intelligence.

NAiSE UWB TAGS

TAGS ARE MOUNTED ON VEHICLES OR EQUIPMENT:

- Send continuous location updates to the anchors.

- Mount at the vehicle’s highest point for clear communication.

- Ensure consistent tracking accuracy across the facility.

COMPATIBLE WITH

SEIDEL: PLANT FRONHAUSEN, GERMANY

The centralized control of our AGVs ensures maximum transparency and flexibility.