Transforming Intralogistics with NAiSE Intralogistics Platform

Excellence in Aluminum and Plastic Packaging

Seidel GmbH & Co. KG is a renowned, family‑owned manufacturer based in Marburg and Fronhausen, Germany, with a rich history dating back to 1830. As a world leader in high‑precision aluminum and plastic design packaging solutions, Seidel specializes in products for demanding global industries where aesthetics, quality, and performance are critical. Seidel’s core expertise lies in the development and production of sophisticated packaging components, including perfume caps, cream jars, lipstick and mascara housings, and other closures and decorative elements. Their solutions are widely used by internationally recognized brands, particularly in the cosmetics industry, where companies such as Dior, Estée Lauder, L’Oréal, and many others rely on Seidel’s precision and design excellence. Beyond cosmetics, Seidel also serves the pharmaceutical, food, writing instruments, and household goods industries, providing packaging that meets strict functional and regulatory requirements while delivering an outstanding visual and tactile experience.

Seidel’s production facility in Fronhausen is organized across multiple interconnected halls, each fulfilling specific roles within the manufacturing and logistics ecosystem. The site includes:

- Production stations for forming, injection molding, surface finishing, decoration, and assembly — all integrating high degrees of automation and precision tooling designed in‑house.

- A high‑bay storage facility to support efficient inventory management, buffer material flows, and rapid dispatch.

- Transfer and buffer zones are strategically placed between production and storage areas to ensure seamless material movement and minimize handling delays.

This structured layout enables Seidel to manage complex production processes efficiently, support high output volumes (hundreds of millions of parts annually), and maintain the flexibility required by its diverse customer base.

Complex, Event-Driven Intralogistics Across Multiple Halls

At Seidel’s Fronhausen facility, material flow is a highly dynamic and time-critical process that spans multiple production areas and interconnected halls. Raw materials, intermediate goods, and finished products move continuously between production stations and storage areas. Key material movements include:

- Transporting newly produced material to storage

- Replenishing production stations based on demand

- Removing full pallets and handling empty pallets

- Moving material across different halls and buffer zones

Material flow is primarily event-driven, triggered by sensor signals or production status updates, and destinations are often determined in real time rather than being known in advance. Intralogistics is therefore a cross-hall task, not confined to isolated areas, requiring seamless coordination and flexibility.

Seidel’s intralogistics ecosystem demonstrates the seamless collaboration of humans, autonomous systems, and smart software to achieve operational excellence. At the heart of the facility, the NAiSE Intralogistics Platform acts as a central orchestrator, connecting vehicles, operators, and IT systems to ensure that materials arrive at the right place, at the right time.

The production halls are served by five state-of-the-art autonomous forklift robots (VDA 5050 compliant), efficiently transporting pallets between production stations and storage areas. In parallel, an autonomous cleaning robot operates across the halls without interrupting production flows. Manual forklifts are planned for future integration, ensuring that human-driven vehicles will seamlessly join the same orchestration ecosystem.

On the digital side, Seidel relies on NAiSE Intralogistics Platform, fully integrated with SAP via a custom RFC interface. This enables two-way communication of transport orders and confirmations, allowing the platform to dynamically respond to production demand. Additional automation and infrastructure—including sensors at NIO and transfer stations, height detection for pallet stacks, and conveyor systems—feed real-time data into the platform, allowing for immediate, event-driven decision-making.

By combining advanced automation, robust software orchestration, and real-time sensor data, Seidel transformed its intralogistics operations from a reactive, manually monitored process into a predictable, reliable, and highly efficient material flow, delivering measurable benefits for both operators and management.

Why Traditional Approaches Were No Longer Sufficient

Before implementing NAiSE, Seidel faced a set of complex intralogistics challenges typical for a high-demand, cross-hall production environment. Coordinating the flow of materials across multiple production halls and storage areas was a daily puzzle. Materials often needed to move quickly and unpredictably, depending on production priorities, which made real-time planning extremely difficult.

Operators frequently had to manually track pallets and material availability, leading to delays, occasional bottlenecks, and time spent on reactive problem-solving rather than on value-adding tasks. Ensuring that production stations were consistently replenished without overstocking was a delicate balancing act, particularly when production schedules changed at short notice.

Integration with existing systems added another layer of complexity. SAP managed the enterprise’s core data, but without a seamless interface, exchanging transport orders and confirmations required manual effort, which slowed down operations and increased the risk of errors.

In short, Seidel needed a solution that could orchestrate complex material flows, provide real-time visibility, and respond dynamically to changing production needs—all while integrating smoothly with their existing technology landscape.

Manufacturer-Independent Orchestration and Real-Time Visibility

To tackle the complex intralogistics challenges at Seidel, NAiSE applied its intelligent platform for intralogistics efficiency, designed to unlock peak performance in material flow while integrating seamlessly with existing systems and workflows. We approached Seidel’s operations holistically, connecting people, vehicles, robots, and IT systems into a unified, intelligent ecosystem.

At the core of our approach is manufacturer-independent orchestration. All transport participants—autonomous mobile robots, manual forklifts, tugger trains, and even specialized equipment—are centrally coordinated to ensure smooth collaboration across the entire facility. The system continuously monitors production demands, inventory levels, and real-time events, dynamically assigning and prioritizing tasks to achieve predictable, transparent, and highly efficient material flow.

By leveraging real-time visibility, event-driven coordination, and data integration, our platform transforms complex cross-hall operations into an agile, responsive intralogistics network. Operators gain a single point of control for managing all resources, while the facility benefits from reduced delays, optimized travel paths, and improved utilization of storage and transport assets.

In essence, NAiSE does not simply move materials—it turns intralogistics into a strategic advantage, bridging the gap between human operations and automated systems, and enabling Seidel to focus on what they do best: producing high-quality products for demanding industries.

The Seidel project clearly demonstrates the capabilities of modern intralogistics orchestration. As Robert Libert, COO of NAiSE, explains, by connecting SAP, autonomous forklifts, cleaning robots, sensors, and operators across multiple halls, NAiSE turned a highly complex environment into a transparent and controllable ecosystem. Remarkably, these performance gains were achieved entirely through intelligent software — without any changes to the physical infrastructure. Libert emphasizes that this is precisely the type of scalable, future-proof intralogistics solution the NAiSE platform is built to provide.

NAiSE Components: Solving Seidel’s Intralogistics Challenges

Seidel faced a complex intralogistics environment with cross-hall material flows, mixed fleets, dynamic production demands, and strict quality requirements. NAiSE Intralogistics Platform addressed these challenges by integrating four core components—Fleet, Order, Traffic, and Warehouse Management—into a unified, intelligent system, while enabling seamless interaction with ERP and other facility systems.

NAiSE FLEET MANAGER: MANAGE THE ENTIRE FLEET WITH ONE PLATFORM

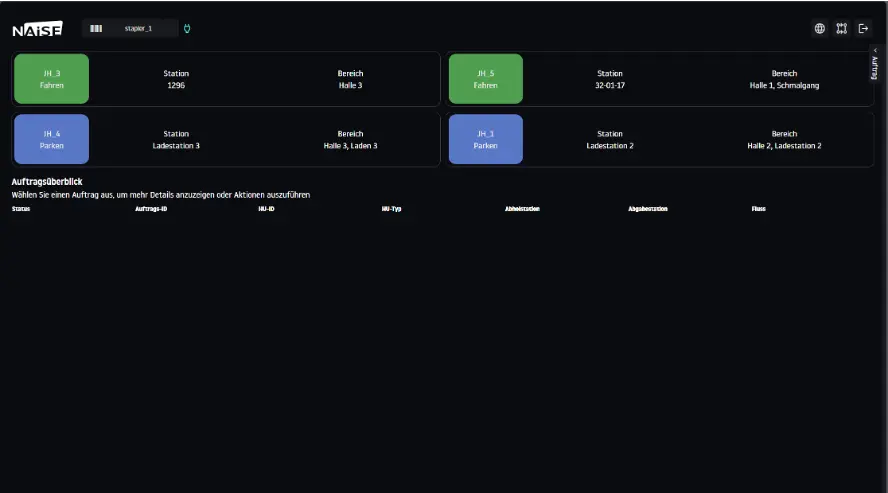

At Seidel’s Fronhausen facility, managing a mixed fleet of autonomous forklifts, a cleaning robot, and future manual vehicles was a complex challenge. The NAiSE Fleet Manager transformed this complexity into seamless coordination, acting as the central brain for all transport participants.

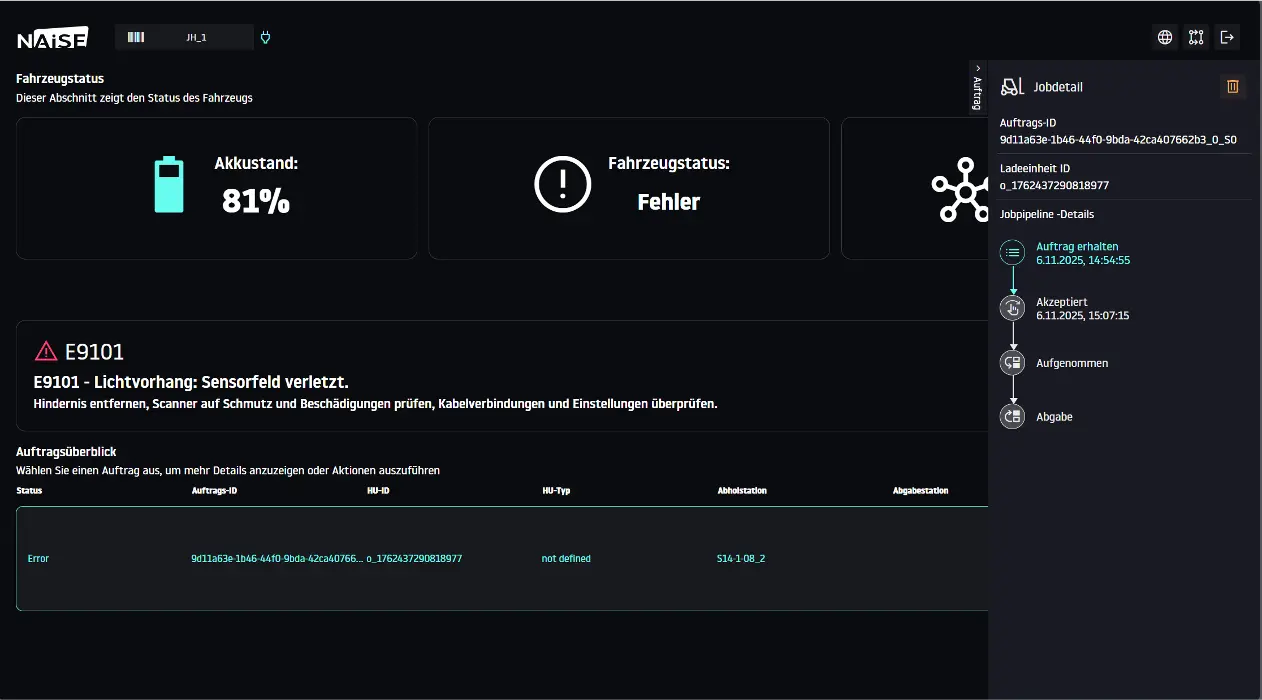

Thanks to real-time tracking and communication, every vehicle—whether an autonomous forklift or a human-driven tugger—operates in perfect synchronization. Operators can monitor the exact position, battery status, and operational health of each vehicle at any moment, and issue commands directly from the platform.

NAiSE TRAFFIC MANAGER: STREAMLINE FLEET TRAFFIC IN MIXED OPERATIONS

In a facility as dynamic as Seidel’s, with multiple production halls, storage areas, and a mixed fleet of autonomous and manual vehicles, traffic coordination is critical. The NAiSE Traffic Manager turned a potential bottleneck into a streamlined, efficient, and safe flow of materials.

By continuously monitoring all vehicles in real time, the Traffic Manager ensures collision-free operations across multiple halls, even when robots from different manufacturers share the same space. Routes are dynamically adjusted based on live occupancy data, sensor inputs, and operational priorities, preventing congestion and downtime.

The Traffic Manager also coordinates the cleaning robot alongside the fleet of autonomous forklifts, using zone-based logic to prevent interference during active transport operations. Sensor signals trigger event-driven task creation, ensuring that traffic flows adapt in real time to production demands. Mixed fleets from different manufacturers operate seamlessly without collision or downtime, highlighting the system’s vendor-independent orchestration.

Additionally, the platform provides traffic analysis and reporting, allowing management to identify trends, optimize routes, and plan fleet expansions without disrupting ongoing operations. This ensures that production and storage areas remain synchronized and that materials move quickly and reliably where they are needed.

NAiSE WAREHOUSE MANAGER: REAL-TIME TRANSPARENCY FOR YOUR INVENTORY

Seidel’s production relies on precise timing and availability of materials across multiple halls and storage areas. The NAiSE Warehouse Manager provided full transparency into inventory, handling units, and station capacities, transforming the way the facility manages its resources.

The Warehouse Manager integrates directly with high-bay storage systems and monitors pallet heights and station capacities via sensors. Empty pallet handling is optimized through automated lookup tables, preventing stacking conflicts and ensuring smooth material flow. Combined with the Order Manager, it supports event-driven pick-only and drop-only orders, making material handling both precise and responsive to real-time production needs.

With real-time tracking, the platform knows exactly where each material is, which station or vehicle holds it, and the current load of every storage or buffer area. This enables:

- Dynamic replenishment of production stations, preventing downtime,

- Optimized use of storage and buffer capacity, ensuring no space is wasted,

- Proactive handling of potential shortages or bottlenecks.

By connecting warehouse data with the Fleet and Order Managers, NAiSE ensures that materials flow seamlessly from storage to production, with every movement visible, tracked, and optimized. Operators can make informed decisions, while the system handles routine coordination automatically, creating a reliable, future-ready warehouse operation.

NAiSE ORDER MANAGER: INTELLIGENT DISTRIBUTION OF MATERIAL FLOW

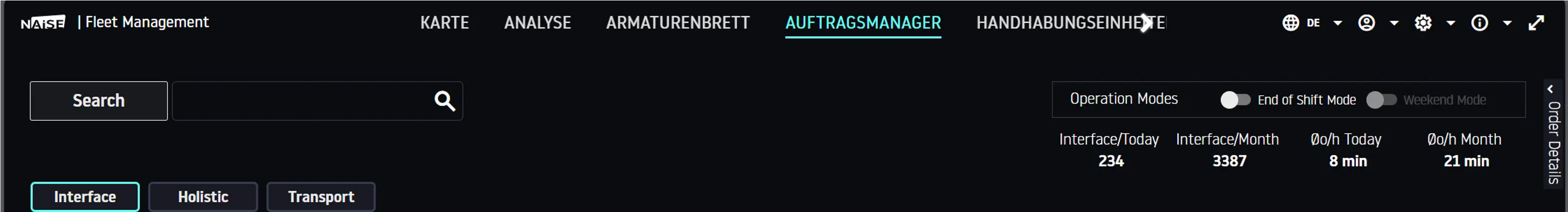

Managing Seidel’s complex material flows required more than standard transport order handling. The NAiSE Order Manager not only translates ERP signals into actionable tasks but also dynamically assigns them to the right vehicle while adapting to real-time facility conditions and exceptional scenarios.

At its core, NAiSE Order Manager:

- Receives transport requests from SAP and converts them into actionable orders,

- Dynamically allocates tasks to vehicles based on availability, proximity, and priority,

- Coordinates seamlessly between autonomous forklifts, manual vehicles, and conveyor systems,

- Monitors the execution of every order in real time.

This standardized approach ensures smooth operation for typical workflows, but Seidel’s facility required enhanced capabilities to handle unique scenarios.

Custom Features Developed for Seidel

Pick-Only & Drop-Only Orders

In cases where the drop-off station is unknown at the time of order creation, the system triggers a pick-only order. Robots pick up the pallet, scan its QR code to retrieve the handling unit ID, and query SAP for the correct destination. Once the destination is identified, a drop-only order is dynamically created and executed. This two-step process ensures full traceability, real-time responsiveness, and flexibility in a highly dynamic production environment.

NIO Station Handling

When a robot carries material, but no active order exists, it automatically delivers the load to a designated NIO/NOK station. This safeguards the material, prevents workflow interruptions, and maintains operational continuity, even in unexpected situations or SAP downtime.

Weekend and End-of-Shift Mode

The system automatically sends robots to park or charging stations at the end of each shift, while all autonomous movements are disabled during weekends. This integration with the facility’s alarm system ensures safety, prevents unnecessary wear, and protects equipment when the facility is not operational.

Order Optimization & Pre-Calculation

Orders are optimized using a shortest-path logic, reducing transport times from 45–50 minutes to 6–20 minutes per order. To further minimize empty driving, operators can define the number of orders to pre-calculate, with support for up to 10,000 orders, providing both efficiency and scalability for high-volume production.

Integration with Fleet, Warehouse, and SAP

The Order Manager operates hand-in-hand with the Fleet and Warehouse Managers, using real-time data to make intelligent task allocation decisions. Integration with SAP via the custom RFC interface ensures that every transport order is synchronized with enterprise systems, delivering full traceability, reliability, and transparency.

Sensor-Driven Precision & Complex Handling Unit Logic

The platform leverages sensors across high-bay storage, buffer zones, and production stations to inform task creation and routing. This includes:

- Pallet height detection for safe stacking and retrieval

- Station capacity monitoring for dynamic replenishment

- Event-triggered order creation based on real-time sensor data

By combining these capabilities with pick-only/drop-only logic and automated fallback to NIO stations, Seidel achieves a level of precision and flexibility that was previously unattainable.

Seamless, Transparent, and Future-Ready Intralogistics

By leveraging the NAiSE Intralogistics Platform, Seidel achieved seamless coordination between autonomous forklifts, cleaning robots, human operators, sensors, and SAP, turning previously unpredictable material movements into a predictable and optimized workflow.

Key benefits include:

- Maximum transparency and control over all transport participants and material movements,

- Dynamic, real-time decision-making that adapts to changing production demands,

- Operational continuity and safety, even during SAP downtime or non-operational periods,

- Significant performance improvements without altering physical infrastructure,

- Scalability and future-proofing, ensuring that the system can grow with production volumes and integrate new technologies.

Through intelligent software orchestration, Seidel now enjoys reduced transport times, optimized fleet utilization, and reliable material handling across multiple halls. The project stands as a benchmark for modern intralogistics, showing how advanced software solutions can deliver measurable efficiency gains, operational flexibility, and a future-ready intralogistics foundation.