HOW AI IS TRANSFORMING SMART FACTORIES?

17.06.2025 | naise.eu

UNLOCKING THE POWER OF ARTIFICIAL INTELLIGENCE

“ARTIFICIAL INTELLIGENCE”– NOT JUST A BUZZWORD

Artificial Intelligence (AI) has been around for decades, but only now is it transforming industries at an unprecedented scale. While AI is often treated as a buzzword, its roots go back to early computer science research, where scientists envisioned machines capable of learning, reasoning, and solving complex problems, just like humans. However, due to limited computing power and a lack of real-world applications, this development stalled throughout the 20th century. The landscape began to shift in the 1980s with the rise of machine learning, yet this approach remained largely theoretical. It wasn’t until recent advancements in computing, automation, and data availability that AI truly took off. With deep learning unlocking new possibilities, Artificial Intelligence has evolved from an abstract concept into a transformative force driving efficiency, automation, and innovation across industries. Today, it is not just a technological evolution; it is a paradigm shift reshaping how we work, interact, and optimize operations.

UNDERSTANDING ARTIFICIAL INTELLIGENCE AND ITS COMPONENTS

AI is a broad field encompassing various technologies that enable machines to simulate human intelligence. The two most prominent subcategories are:

- – Machine Learning (ML): The ability of machines to learn from data without being explicitly programmed. ML algorithms improve over time as they process more information.

Example: Predicting which AGVs will need maintenance soon based on past movement and performance data.

- – Neural Network (NN): Systems inspired by the human brain, consisting of interconnected nodes (neurons) that process information.

Example: Recognizing patterns in error messages to automatically suggest solutions.

- – Deep Learning (DL): A more advanced form of ML that utilizes artificial neural networks to recognize patterns, make complex decisions, and even understand human speech and images.

Example: Optimizing robot traffic flows within a dynamic shopfloor layout.

These technologies are the foundation of automation, predictive analytics, and smart decision-making across industries, including intralogistics. By processing large volumes of data, AI can detect patterns, forecast operational needs, and adjust workflows dynamically. As a result, it is enabling smart factories to streamline their operations and meet the growing demand for precision and efficiency.

AI AS A PARTNER, NOT A REPLACEMENT: OVERCOMING SKEPTICISM IN THE WORKFORCE

Despite the immense potential of Artificial Intelligence, many workers remain skeptical, especially in manual jobs like intralogistics. There is a concern that this new advancement might replace human workers, but the reality is quite different. This technology is not designed to replace the workforce; rather, it serves as a powerful partner that helps guide everyday operations, making processes more efficient, improving productivity, and enhancing quality and performance. By leveraging AI and its components, industries can tap into new levels of insight and precision, helping workers make better decisions and reducing the strain of manual tasks.

Much like online platforms have adopted AI to enhance decision-making by tailoring recommendations on streaming services, shopping platforms, and social media, this smart technology will soon play a similar role in intralogistics. Through the vast collection of data generated in the intralogistics environment, AI systems will be able to predict potential outcomes, make real-time decisions, and optimize resource allocation. This approach will not only streamline operations but also help businesses be more adaptive and responsive to changes in demand, ultimately fostering a more efficient, productive, and harmonious work environment.

TACKLING THE CHALLENGES OF AUTOMATED INTRALOGISTICS

Although automation has significantly improved warehouse and production processes, facilities still face persistent challenges that hinder efficiency and increase costs. In recent years, many factories and distribution centers have turned to mobile robots, such as AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots), to enhance their intralogistics operations. These mobile robots help streamline material flow, reduce manual labor, and improve overall throughput. However, despite their advantages, integrating mobile robots into operations comes with its own set of challenges.

One major issue is the unplanned downtime of AGVs and AMRs due to battery failures. Without predictive insights, managing energy levels becomes difficult, leading to unexpected shutdowns that disrupt operations. Inefficient charging schedules only worsen the problem, causing unnecessary delays. Another challenge is fleet allocation, as determining the right number of vehicles remains a constant struggle. Deploying too many increases costs and creates congestion, while too few lead to bottlenecks and slowdowns. Without accurate forecasting, facilities risk either wasting resources or falling short of capacity, both of which impact productivity. Error detection and root cause analysis add to these difficulties. Malfunctions can stem from hardware failures, software glitches, or environmental factors, yet traditional troubleshooting methods are slow and reactive. Without intelligent systems to classify errors and identify their sources, downtime extends, reducing overall efficiency.

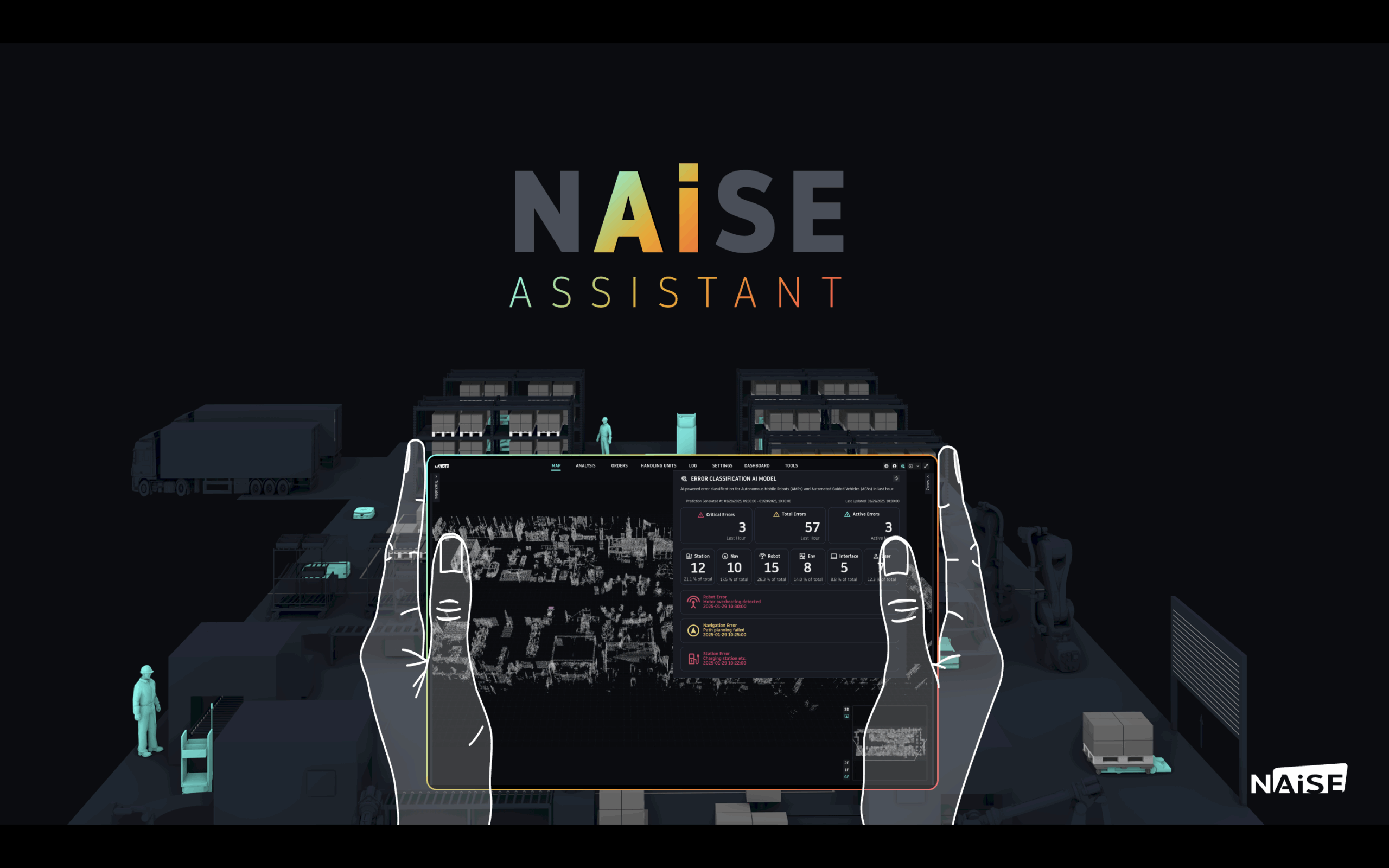

NAiSE: PIONEERING AI IN AUTOMATED INTRALOGISTICS

Recognizing the growing demand for AI-powered optimization and to solve mentioned challenges, NAiSE has developed advanced AI models into its Intralogistics Platform. Initially developed to meet specific customer needs, these AI models have evolved into a scalable solution for optimizing mobile robot operations.

The AI models developed by NAiSE include:

- – Battery Level Prediction: Enables proactive energy management by forecasting the remaining battery life of AGVs and AMRs. This prevents unexpected downtimes by aligning charging schedules with operational needs. The model dynamically adapts to usage patterns, vehicle type, and historical charging behavior, ensuring vehicles stay mission-ready without overloading charging stations or wasting energy.

- – Holistic Order Number Prediction: Provides a comprehensive forecast of total transport and production orders expected across the entire plant. It’s built specifically for each environment, using historical production data, shift schedules, and seasonal patterns to anticipate future workloads. This model informs overall resource planning and allows other predictive modules to operate with greater accuracy.

- – Transport Order Number Prediction: Focuses on forecasting the volume and timing window of upcoming transport tasks, based on ongoing production and intralogistics activities. The model runs periodically, predicting the number of orders expected in the next hour, enabling dynamic adjustment of fleet deployment, routing, and staging operations by anticipating demand patterns in advance.

- – Error Probability Prediction: Continuously monitors operational data from vehicles and system components to estimate the likelihood of faults occurring. The model is trained on historical error data and analyzes which specific trackable statuses tend to lead to faults, using input from a diverse fleet of robots.

- – Error Classification Model: Quickly identifies and categorizes any type of error that occurs, helping operators and support teams react faster and more precisely by distinguishing between navigational, environmental, interface, user, or robot issues.

By embedding these models into its platform, NAiSE is pushing the boundaries of what’s possible in smart factories. Unlike traditional rule-based intralogistics systems, which require constant manual adjustments, NAiSE’s AI models continuously learn and refine their algorithms, ensuring a self-optimizing, adaptive intralogistics environment.

As AI systems become more involved in daily decision-making, it’s essential they remain explainable and fair. NAiSE is committed to building ethical AI by ensuring its models:

- – Are trained on diverse, unbiased data,

- – Provide understandable insights (not black-box outputs),

- – Complement human decision-making, not override it.

Transparent dashboards, operator feedback loops, and human-in-the-loop strategies ensure that AI augments, not automates blindly.

FROM DATA TO DEPLOYMENT

Developing robust AI models requires more than just algorithms—it demands a structured and iterative approach to ensure accuracy, adaptability, and real-world applicability. At NAiSE, our AI development process follows these key steps:

- 1. Data Collection & Processing: We gather extensive datasets from intralogistics operations, like robot movement data, order volumes, and error logs. Cleaning, structuring, and annotating this data ensures that our models have high-quality inputs to learn from.

- 2. Feature Engineering: We extract and refine the most relevant patterns and attributes that contribute to predictive accuracy, ensuring that our models focus on meaningful indicators rather than noise.

- 3. Data Splitting: To train models effectively, we divide the dataset into training, validation, and testing subsets,allowing us to fine-tune algorithms and avoid overfitting.

- 4. AI Model Selection: Based on the problem, we determine whether a model should be built using machine learning, deep learning, or NLP approaches. This decision depends on factors such as data complexity, interpretability, and real-time processing needs.

- 5. AI Model Training & Evaluation: Using iterative training processes, we optimize model performance by continuously refining hyperparameters and evaluating against the most relevant metrics, such as accuracy, precision, recall, or error rates, depending on the model type and use case.

- 6. Intensive Testing & Deployment: Before rolling out any model, we conduct rigorous testing in real-world intralogistics environments. This ensures that our AI solutions function reliably under actual production conditions, rather than just in controlled simulations. Once validated, the models are seamlessly integrated into our app through an intuitive, user-facing GUI, making AI insights directly accessible within daily operations.

REAL-WORLD VALIDATION AND THE DIAZI PROJECT

Unlike many AI-based projects that remain confined to research settings, NAiSE is committed to deploying and testing these models in real-world working environments. Our predictive models will be validated in live intralogistics operations and undergo real-world testing with actual AGVs and AMRs at several customer plants. By processing real-time fleet management data, error reports, and operational workflows, our models will adapt dynamically to true production conditions, ensuring that they are not just theoretically sound but also industrially effective.

By continuously testing in real-world applications, NAiSE ensures that its AI-powered intralogistics solutions remain adaptive, scalable, and future-proof. The result is a self-optimizing intelligent system that improves over time, delivering increased efficiency, reduced downtime, and smarter decision-making capabilities across automated logistics environments.

NAiSE is also playing a pivotal role in the digital transformation of manufacturing as a key partner in the DIAZI project, a groundbreaking initiative focused on digitalizing the entire production process in the automotive and supplier industries. NAiSE AI-powered solution aligns perfectly with DIAZI’s vision of a fully digitalized, data-driven factory, where every component of production is seamlessly interconnected. In the early stages of the DIAZI project, the AI models have already contributed to reducing inefficiencies and streamlining workflows in real-world plants. As the project continues to evolve, the AI-powered error classification system will be implemented across several production facilities, helping to optimize resource allocation and minimize disruptions. The integration of this AI technology marks the beginning of a new era in AI-assisted intralogistics, where plants are interconnected and capable of adapting to evolving market demands and complex supply chains.

THE FUTURE OF ARTIFICIAL INTELLIGENCE IN INTRALOGISTICS

AI is more than just an industry trend – it is a transformative force shaping the future of intralogistics and manufacturing. As factories move towards full automation and smart manufacturing, AI will play a crucial role in creating resilient, self-learning systems that minimize inefficiencies and maximize productivity. NAiSE is leading this transformation by integrating AI-powered solutions into intralogistics, ensuring that businesses stay ahead in the era of Industry 4.0. By educating the market and providing cutting-edge intelligent applications, NAiSE is setting new standards in warehouse and production intralogistics.

The revolution is already here, and AI is the driving force behind it. As companies embrace these advancements, they will unlock new levels of efficiency, reliability, and intelligence, ushering in a new era of autonomous, self-optimizing intralogistics.